Carbonated beverages are unquestionably a big hit here in the United States. Whether it’s soda or beer, consumers love them. And when there’s demand for such beverages, it only makes sense that manufacturers continue to churn out the products.

Simply put, carbonated beverages are those that contain carbon dioxide dissolved in water, which thereby creates a fizzing and bubbling sensation in the particular drink. While carbonation can occur naturally, when it comes to carbonated beverages like sparkling water, beer and soda, the carbonization is completed artificially in an industrial plant. Consumers enjoy carbonated beverages for the fizzing taste and manufacturers enjoy making such drinks because they’re easy to distribute and the carbonization gives such beverages a long shelf life.

But, believe it or not, there’s a lot that goes into a carbonated beverage line, from carbonatorequipment to filling equipment, in order to ensure that consumers get the beverages that they enjoy so much. This post will cover some of the basics behind a carbonated beverage line, and what you need to know about much of the equipment that makes these types of drinks possible. Here’s a closer look:

Equipment in a Nutshell

As we noted in the opening, there is a lot of equipment that is needed for a carbonated beverage line. This equipment variety consists of things like mixing and blending units, sugar dissolving equipment, carbonators, homogenizers, pasteurizers, heat treatment machines, fillers and cappers, labeling equipment and packing equipment. While this line can be extensive, especially when you consider the packaging components that make the distribution of the beverages viable, each piece of equipment plays a unique role. We’ll cover some of the more notable pieces of equipment on a carbonated beverage line in the section below.

Key Pieces of Equipment

- Mixing and Blending Units: Sodas come in all sorts of different types of flavors – and it seems that new ones are always coming out. Yes, there’s no shortage of mixing and blending when it comes to creating carbonated beverages, and this is a task that’s often completed very early in the creation of a beverage. Normally, this mixing and blending is carried out in a continuous motion.

- Storage Tanks: A carbonated beverage line is likely to need several storage tanks, which help carry out several key processes, such as coagulation, filtration and chlorination. These processes are all designed to remove impurities in the water mixture that’s involved in the beverage making process. Keep in mind that carbonated water makes up over 90 percent of what is in a soft drink, so the processes that make the water pure and viable for this process cannot be underestimated.

- Carbonators: While mixing and blending equipment help create the flavor, it’s the carbonatorsthat fittingly add the carbonation. Essentially, they are what makes a drink a carbonated beverage. The main component of a carbonator is the carbonation tank, which pumps fresh water and carbon dioxide at high pressures. This is then diffused and the water absorbs the gas into a solution. Carbonators are arguably the most important component in the beverage line – they’re also pieces of equipment that require a lot of maintenance in order to continue to perform up to their full potential.

- Carbo Coolers: Carbo coolers are similar to carbonators, except they also cool the liquid beverage at the same time that they carbonate the beverage.

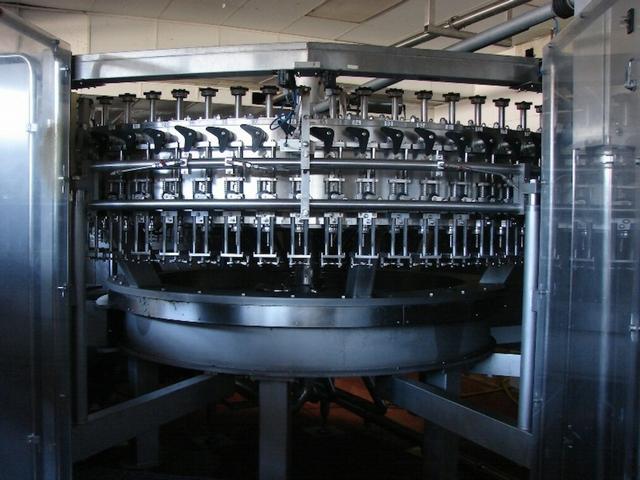

- Filling and Sealing Machines: While carbonators might get all of the glory in the beverage line for taking a liquid and actually making it a carbonated one, filling and sealing machines help a beverage stay that way. And that’s why filling and packaging is so important when it comes to carbonated beverages, because if it isn’t transferred into either bottles or cans at very high flow rates and then sealed immediately, it will lose its carbonation and become “flat.” That’s why containers, whether they be bottles or cans, are normally immediately sealed with pressure-resistant closures.

- Labeling: When it comes to soft drinks and beer, packaging and labeling is very important in order to convey the brand. And while labeling is a big part of the tail end of a carbonated beverage line, it’s worth noting that it is not without its challenges. Labels for such beverages are usually made of either plastic film or paper, but in order to ensure the integrity of the label and that it doesn’t fail, the bottles or cans must be brought back up to room temperature to prevent condensation and ensure that the label will stick. Because they’re often cooled during the carbonation step, cans and bottles are usually hosed down with warm water to bring their temperatures up. Only then can the labels be applied.

- Palletizing Accessories: After the beverage has been filled and sealed in either a bottle or can, then it must be distributed. To get the product to distributors, companies usually pack them onto trays or pallets to make shipping easier.

Beverage Line Equipment: A Big Capital Investment

We just highlighted some of the components that are involved in a carbonated beverage line, but make no mistake about it, there is quite a bit more that is involved in such an operation. Another similarity between most of the equipment that you’ll need on a carbonated beverage line is the high cost of it. Yes, such equipment isn’t cheap, with pieces ranging from several thousand dollars to tens of thousands of dollars to even hundreds of thousands of dollars.

Noting the high cost of equipment, this can unquestionably put manufacturers in a bind if a piece of equipment were to fail unexpectedly. When this occurs, there is a decision to be made – buy a brand new piece of equipment for market value or buy a used and refurbished piece of equipment that works like new but is a bit cheaper. There’s no real right or wrong answer, just situations to be aware of. And for the company that didn’t budget for a new piece of equipment, the used route may be the ideal way to go, especially if its acquired from a quality, credible source like Bid on Equipment.

For more information on Bid on Equipment, and to browse the company’s library of used and refurbished equipment for a carbonated beverage line, contact the company today.